Tower Crane Cable Failure Prevented

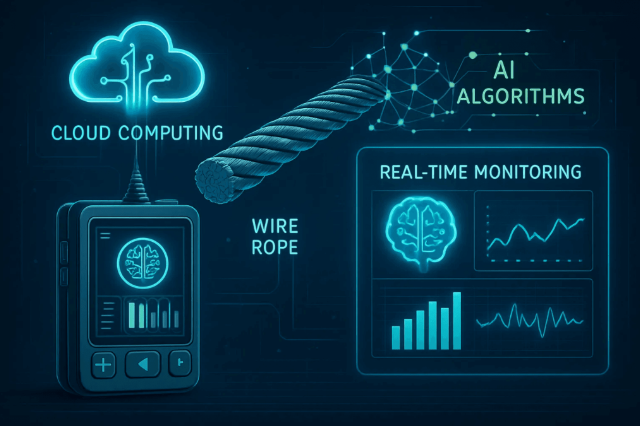

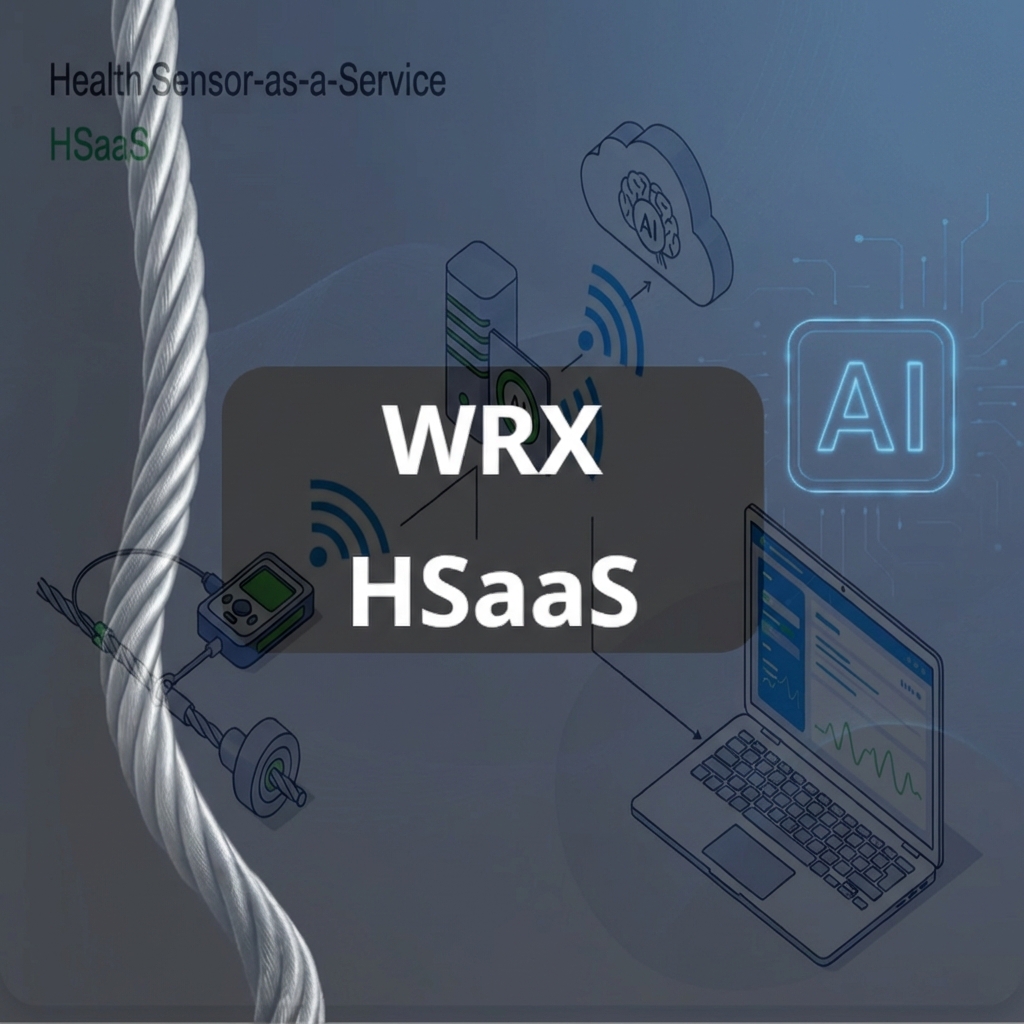

Prevented critical security from Crane Cable Failure. Prevented "Secondary Knot" on the Boom hoist rope line on a Construction Tower Crane. A local inspection service had checked the cable 3 weeks section loss, halting operations and preventing a catastrophic drop caused by whiplash.